Tackling the E-Waste Menace in India

- BY Sonal Khetarpal

In Innovation

In Innovation 15738

15738 0

0

A report released by IT trade body ASSOCHAM in September 2013 reveals that Bangalore is soon to become the country’s e-waste hub generating about 18,000 tonnes of e-waste a year, growing at a compounded rate of 20 per cent per year. Following Bangalore is Mumbai at 10,000 tonnes a year, and then Delhi and Chennai.

Source: Manufactures Association for Information Technology

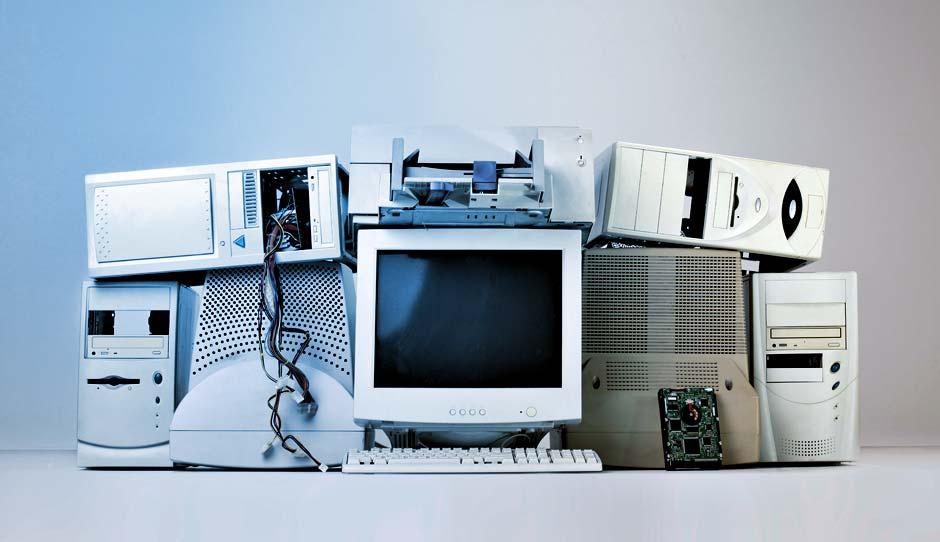

Source: Manufactures Association for Information Technology E-waste refers to discarded electrical and electronic devices—mobiles, computers, tubelights, bulbs, wires, cables, refrigerators. When intact, these devices don’t pose any threat. But, when dismantled and dumped in the scrapyards or landfills, the harmful metals present in them such as lead, chromium, mercury seep into the environment and contaminate it. They also affect the scrap dealers who dismantle the e-waste without any proper equipments as they burn the components in the open which leads to emission of poisonous gas fumes.

The Indian government woke up to the colossal problem of e-waste a bit late and proposed a draft e-waste policy, e-waste (Management and Handling) Rules, 2010. These rules were gazette notified in 2011 and came into effect in May 2012.

By then, Dr P. Parthasarathy had already been working to counter the e-waste problem for several years. Parthasarathy used to work in Singapore in the early 2000s for a recycling company that specialised in precious metal recovery from discarded electronic equipments. In 2004, he moved back to Bangalore to start E-Parisaraa, an electronic waste recycling company, both to provide solutions to a mammoth problem, and to cash in on the right market opportunity.

Today, Parthasarathy claims E-Parisaraa is India’s first e-waste recycling company to be approved both by the Central Pollution Control Board and the Karnataka State Pollution Control Board. Their first processing unit is located on a 1.5 acre land in Dobaspet which is around 50 kms from Bangalore, an area that has been earmarked by the government for hazardous waste management.

But, how does e-waste recycling work? Companies such as E–Parisaraa buy obsolete and discarded electrical equipments from electronic manufacturers or bulk consumers of electronic devices such as corporates and institutions. The average price that these recyclers give for e-waste is Rs30-40 per kg. Plastic items are sold for relatively less price, around Rs15 per kg, informs Parthasarathy. These companies then bring back the e-waste to their processing unit to be dismantled. All components are segregated into glass, plastic and metal. These are sold to different manufacturers who use these recycled product waste as raw material. For instance, the copper in your desktop can be used to make electric wires, and the silver and gold in your mobile phones can be used for plating of imitation jewellery.

E-Praisarra's e-waste processing capacity is 10,000 tonnes annually but it recycles only one-fourth of that.

It might sound like a logical win-win that everybody works towards. However, things haven’t been easy for E–Parisaraa. Its e-waste processing capacity is 10,000 tonnes annually across five facilities in Bangalore, Chennai, Mumbai, Gurgaon and Kolkata but they recycle only one-fourth of that.

These problems are echoed by other e-waste recyclers as well. For instance, K.P.K. Kumaran, founder of Chennai-based e-waste management and recycling company Earth Sense, says they have been getting only 2,000 tonnes (10 per cent of the capacity) of their processing capacity of 20,000 tonnes across their three recycling plants in Mumbai, Gurgaon and Hyderabad since the last five years. Clearly, there is no dearth of obsolete electrical items in India. So, the pertinent question is where does it all go.

Source: Manufacturers Association for Information Technology

Source: Manufacturers Association for Information Technology Parallel to these authorised e-waste recycling company exists a separate world of informal recyclers that also buys e-waste. This informal sector does not recycle, but refurbishes the goods and sells them again in the secondary market. Reselling of refurbished goods gets a much higher price than selling of processed recycled metals to manufacturers. Due to this, the informal sector pays a better price for e-waste that goes up to Rs100 per kg of e-waste. “If we pay more than Rs45 per kg of e-waste to companies, we are out of business,” says Parthasarathy.

This problem is worsened due to the easy procedure for obtaining recycling authorisation for e-waste. Anyone with barely two or three employees can also get a license, says Parthasarathy. Due to this a lot of people from informal sector become authorised dealers for recycling and can legitimately take part in auction of e-waste in companies. This increases the competition for genuine recyclers as they bid for a higher price for e-waste. “Since companies get better price from informal sector they are more keen on selling to them and make end-of-life profits rather than properly disposing off their electrical equipments,” says Parthasarathy.

To counter this, Parthasarathy says companies like his need to launch massive awareness campaigns. So, along with Umicore Precious Metals Refining, Belgium-based world’s largest precious metals recovery company, E-Parisaraa started a programme called Crystal Project in May 2010. Under this project, they bought e-waste from the informal sector so that they can dispose off the e-waste safely. Although they had launched it for a year, the project’s success has ensured it continues till today. In 2011, they also launched a vehicle that would go around the city collecting e-waste.

Earth Sense also partnered with the NGO, Ishta Foundation to spread awareness about the importance of recycling e-waste in corporates, schools and colleges and created the website, welovetorecycle.com. Only after working aggressively on it for three years, from 2005 to 2008, the companies giving them e-waste increased from 150 tonnes to 1,000 tonnes. As Earth Sense’s CEO John Robert informs, “Initially, almost 60 per cent of the companies we approached refused to even meet us .”

However, the problems voiced out by these recycling companies remain far from being solved. As per the survey done by E-Parisaraa last year in 2013, 80 per cent of the e-waste produced in Bangalore still goes to the informal sector. There are also many clauses remaining to be included in the e-waste policy. The e-waste rules does not have any guidelines about the occupational health and safety of workers. Also, the government has missed lighting equipments such as tubelights and bulbs from the e-waste category. The policy does not mention a unified set of authorisations that recyclers require from Pollution Control Board. Due to that, recycling companies have to obtain licences from each state they operate in which is a very time consuming process as each state has a different set of regulations, says Robert.

Clearly, the journey from trash to treasure is unlikely to become a smooth run anytime soon. Hopefully, entreprenuers like Mittal and Parthasarathy are fuelled by perseverance and grit, and can stay the course and soon make treasure from trash.

Add new comment